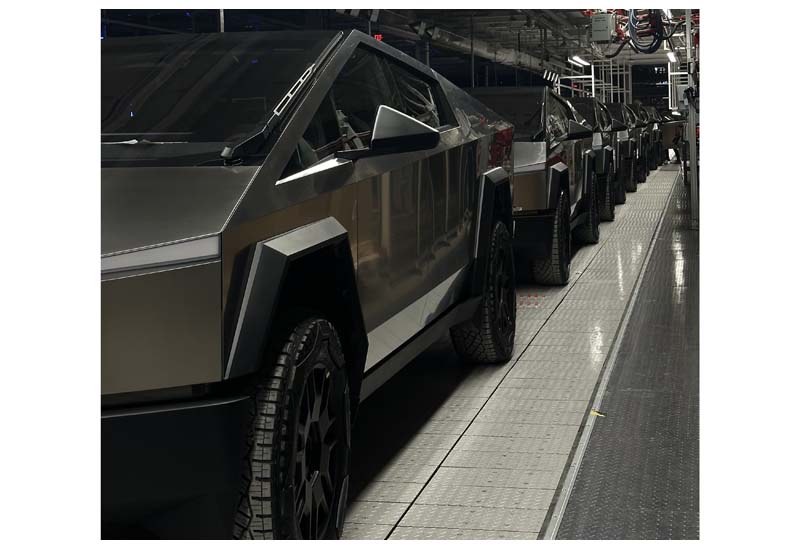

Tesla has unveiled the world’s first dry cathode Cybertruck, marking a significant milestone in electric vehicle. This innovation represents a major step forward in Tesla’s ongoing efforts to enhance battery efficiency and reduce production costs.

The announcement came from Bonne Eggleston, Sr. Director of Tesla’s 4680 team, who confirmed that this Cybertruck is equipped with the first-ever dry cathode 4680 cells. Eggleston noted, “CoG is surprisingly similar considering it’s carrying the weight of five years of blood sweat and tears.” This statement underscores the immense effort and innovation that went into this achievement.

Tesla’s commitment to in-house production is evident in Eggleston’s assertion that the cells are “fully made by Tesla on our mass production scale dry electrode machines.” This approach aligns with Tesla’s strategy to control more aspects of its supply chain and manufacturing process.

The introduction of dry cathode technology in the Cybertruck has far-reaching implications for Tesla’s battery strategy. At the company’s recent annual meeting, several key points were highlighted:

- Tesla sees a clear path to making the 4680 cell the most competitive from a manufacturing efficiency standpoint.

- In-house cell production provides Tesla with resilience against geopolitical changes, ensuring independence in a critical component of EV manufacturing.

- The company’s cathode and lithium refineries represent a significant improvement over traditional facilities, with Tesla emphasizing cleanliness and efficiency.

Despite current higher costs for in-house cell production compared to external sourcing, Tesla remains optimistic. The company anticipates achieving cost parity between in-house and externally sourced cells by the end of the year, although they acknowledge this goal will be challenging.

Interestingly, Tesla notes that the most significant cost reduction opportunities now lie in other areas of vehicle production rather than the battery pack itself. This shift indicates the rapid progress made in battery technology and manufacturing.

Cole Otto, Senior manufacturing engineer for 4680 cell development at Tesla posted this on social media: “Introducing the first-ever Dry Cathode Cybertruck! In July, we kicked off vehicle testing with our groundbreaking in-house dry cathode 4680 cells. This is a significant milestone in advancing both technology and cost efficiency. Proud to be part of the brilliant team that made this historic achievement possible!”

Tesla’s advancements in dry cathode technology and 4680 cell production could potentially reshape the EV industry. If the company successfully scales this technology, it could lead to faster production and lower costs, further solidifying Tesla’s position as a leader in the EV market.

Moreover, these developments are not just about cost reduction. They also represent a strategic move to mitigate risks associated with the global battery supply chain, particularly given China’s dominant position in battery production.

Related Post: Tesla Battery Bottleneck Threatens Cybertruck, Unable to Scale 4680 Cells for Mass Production?