In a surprising demonstration of engineering prowess, Tesla’s Cybertruck has proven itself capable of far more than advertised. Popular tech YouTuber ZacksJerryRig recently put the vehicle’s towing capabilities to an extreme test, revealing that the Cybertruck’s hitch can handle forces nearly ten times beyond its official rating.

The test, which quickly went viral across social media platforms, showed an excavator applying downward pressure on the truck’s hitch until failure—which didn’t occur until reaching a staggering 10,400 pounds. This remarkable performance has sparked conversations about Tesla’s conservative ratings and the true capabilities of the Cybertruck’s aluminum castings.

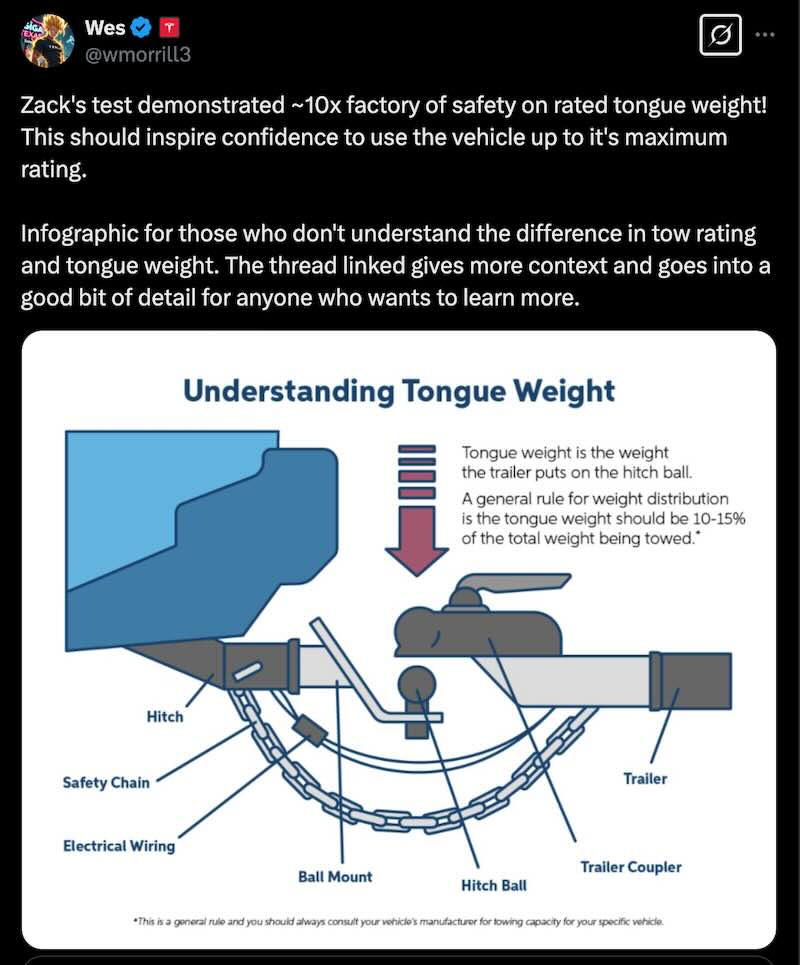

For those unfamiliar with towing mechanics, there’s an important distinction to understand. A vehicle’s towing capacity refers to the total weight it can pull, while tongue weight specifically measures the downward force applied to the hitch by the trailer.

According to Tesla’s official documentation, the Cybertruck boasts an 11,000-pound towing capacity with a corresponding tongue weight rating of 1,100 pounds—exactly 10% of the total capacity, which follows standard automotive engineering practices.

This 10-15% ratio isn’t arbitrary. It’s rooted in physics and represents the optimal balance for safe towing. When properly distributed, this weight keeps the rear wheels planted and prevents the hitch from bouncing, creating a stable towing experience. Too much tongue weight overloads the rear and compromises steering control, while too little creates dangerous lifting forces that can make the vehicle unpredictable at highway speeds.

What makes ZacksJerryRig’s test particularly noteworthy is just how far beyond specifications the Cybertruck performed. Zack’s initially expected failure much earlier, but had to reposition the excavator closer to generate enough force after the hitch easily handled 8,000 pounds.

When the connection point finally gave way at approximately 10,400 pounds, it had withstood nearly ten times its rated capacity—a safety margin that’s practically unheard of in automotive design.

Wes, identified as a Cybertruck Lead Engineer, commented on the test results: “Zack’s test demonstrated ~10x factory of safety on rated tongue weight! This should inspire confidence to use the vehicle up to its maximum rating.”

Wes: Zack’s test demonstrated ~10x factory of safety on rated tongue weight!

He also addressed concerns about real-world implications: “At 10,000 lbs of tongue weight, the vehicle would be so grossly misloaded the front wheels would no longer be on the ground. And to answer a common question—no, a pothole will not transfer this much vertical force to the hitch.”

The Cybertruck’s performance has reignited discussions about material choices in truck manufacturing. Traditional pickup trucks typically use steel frames, while Tesla opted for aluminum castings in the Cybertruck design.

In his video, Zack points out the differences in failure characteristics between cast aluminum and steel tubing. While aluminum can be more brittle under certain conditions, the test results suggest that Tesla’s implementation provides exceptional strength for normal use cases.

Despite this strength, it’s worth noting that the Cybertruck does have specific limitations. When accepting vertical loads without a trailer attached, the maximum rating drops to just 160 pounds. Fact that the frame withstood 65 times this limitation before failing further demonstrates the significant engineering margins built into the design.

While impressive, these extreme test results shouldn’t encourage owners to exceed manufacturer specifications. 1,100-pound tongue weight rating represents the maximum safe load for everyday use, accounting for various real-world conditions including road surfaces, speed, and dynamic forces.

What the test does reveal is the substantial safety margin Tesla has built into the Cybertruck design. Over-engineering approach may provide additional confidence for owners who regularly tow at or near the vehicle’s rated capacity.

The conversation around the Cybertruck’s structural integrity is particularly relevant given recent discussions about its reliability. According to the information provided, there have only been three known instances of frame failures related to towing—two from intentional destructive tests (including ZacksJerryRig’s experiment) and one unconfirmed real-world case with limited details.

This scarcity of failures, coupled with the extreme conditions required to cause damage in controlled tests, suggests that the Cybertruck’s hitch design is more than adequate for its intended use when properly loaded.

Perhaps the most significant aspect of this test isn’t just that the Cybertruck exceeded expectations, but by how much. Engineering typically involves balancing weight, cost, and strength, with safety factors built in to handle unexpected conditions. A component that can withstand ten times its rated capacity indicates either extremely conservative ratings or exceptional design margins.

For potential Cybertruck owners who plan to use their vehicles for heavy towing, these results provide reassurance that Tesla’s engineering team has created a towing system with substantial reserves beyond everyday requirements.

Related Post

Cybertruck Earns Top NHTSA Safety Score: Wes Revealed Engineering Crumple Zone Secrets

Tesla Cybertruck Champion: Wes Morrill Earns Spot on TIME’s Climate Leaders List

Tesla Cybertruck: Safety Features and PowerShare Technology Revealed