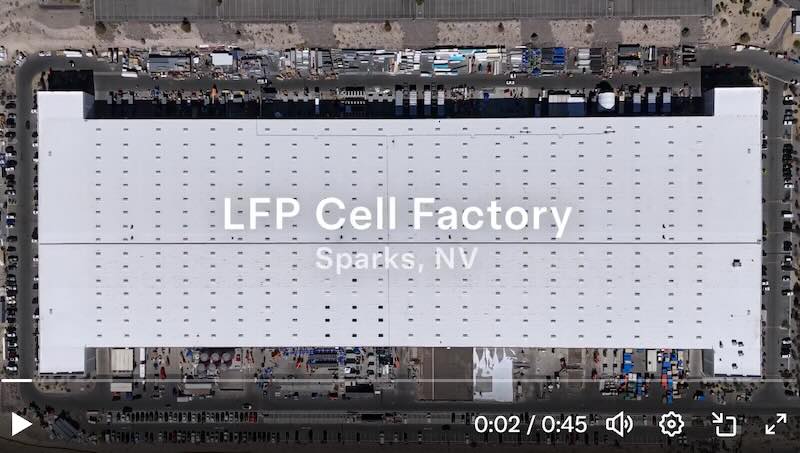

Tesla has quietly advanced toward completing its first lithium iron phosphate battery cell manufacturing facility in North America. Nevada-based plant represents a strategic shift away from Chinese suppliers and positions the company to produce affordable energy storage solutions domestically.

Currently, Tesla imports all LFP batteries for its Megapack energy storage systems from Chinese manufacturers. New Tesla LFP battery factory will reduce geopolitical risks while potentially lowering production costs through proprietary cell designs that patents suggest could undercut even Chinese-sourced alternatives.

Domestic production facility addresses regulatory challenges that have impacted Tesla’s vehicle lineup. Tesla previously discontinued lower-cost, standard range vehicles with LFP batteries in the United States because imported batteries failed to meet EV credit sourcing requirements.

With local production, Tesla can now claim the 45x manufacturing credit for battery modules and inverters, directly reducing operational costs. While future policy changes under different administrations remain uncertain, domestic manufacturing provides stability regardless of shifting political winds.

Analysis of factory footage reveals several key details about the Tesla LFP battery factory operations. Production line appears to utilize wet coating processes rather than dry coating technology, evidenced by visible drying ovens in facility images.

Three factors likely influenced Tesla’s decision to implement wet coating processes. First, equipment acquisition from Chinese manufacturer CATL approximately 18 months ago provided cost-effective machinery designed for wet processes. Second, Tesla continues refining its dry coating technology for 4680 cells, making wet processes more practical for immediate deployment.

Evidence suggests the facility will produce prismatic cells rather than cylindrical formats. Tesla indicated during recent earnings calls that these cells target grid storage applications, where prismatic designs offer superior performance characteristics. Additionally, the suspected CATL equipment primarily handles prismatic cell production.

Factory footage at the 35-second mark appears to show prismatic cells in production areas, supporting this configuration assumption.

Industry analysts expect the Tesla LFP battery factory to reach volume production within one to two years. Initial capacity rumors suggest 10 GWh annual output, representing a modest but meaningful first investment in domestic LFP production.

Tesla will likely expand in-house LFP prismatic cell manufacturing significantly over time, potentially incorporating lessons learned from dry coating 4680 production lines in Austin facilities.

For Tesla, this represents more than manufacturing expansion—it’s about making their energy independence less dependent on foreign suppliers while keeping costs competitive. Nevada facility proves Tesla isn’t just thinking about batteries; they’re manufacturing their future LFP success.

Related Post

Tesla 4680 Battery Cell Production Soars: 100 Million Milestone Reached

Tesla Supply Batteries Chain Independence Tackles China Dependency Risk

NIO Supplies McLaren with Advanced 4680 Battery Cells for Hybrid Supercars