Tesla’s Q2 earnings 2023 released early this morning mentioned that they are currently testing the final validation of Cybertruck around the world, and that this vehicle will break many boundaries, both technologically and structurally, which is very consistent with Tesla’s philosophy on vehicle engineering.

Tesla Q2 2023 earnings call reveals plans to license FSD: What You Need to Know

Tesla said that Cybertruck is still on track to start production at the Texas factory later this year and start deliveries within the year.

At the same time, Tesla has also made some progress on the new platform. At the Tesla Investor Day earlier this year, Tesla introduced the third gen vehicle platform currently under development. The new platform will have a higher level of integration, and the production cost of vehicles is expected to be cut in half – approximately half of the current level.

The 4680 battery, which has been unveiled for many years, will also achieve real large-scale production on the new platform.

According to Power On, Tesla’s 4680 battery production line has reached 150PPM (battery production capacity unit, producing 150 cells per minute), almost 10 times that of the current ternary rectangular battery.

Of course, compared to making batteries, Tesla is obviously more skilled at making cars. The earnings report shows that Tesla produced nearly 480,000 vehicles in the second quarter and successfully delivered 466,000 of them. Specifically, the Model 3 and Model Y accounted for 95.9% of the total production, while the two luxury models, Model S and Model X, accounted for 4%.

At the same time, the record delivery volume also brought Tesla’s total revenue to a new level.

Tesla’s total revenue in the Q2 by 47% year-on-year to $24.9 billion. But due to price cuts, increased costs of 4680 mass production, and increased operating expenses caused by Tesla Cybertruck, AI and other projects, second quarter operating profit decreased slightly year-on-year to $2.4 billion, with an operating profit margin of 9.6%.

Despite the slight decline, the operating profit margin of around 10% is still at a healthy level, especially against the backdrop of two consecutive quarters of price cuts. Tesla said this reflects their continuous efforts to reduce costs.

However, when asked when the cost per vehicle could be lower than $36,000, the Tesla spokesperson said it was hard to say.

“We bear a variety of costs, many of which are beyond our control,” the spokesperson said. “On the other hand, Tesla also faces tremendous inflationary pressures.”

But without a doubt, Tesla’s biggest advantage still lies in its strong large-scale production capability, which continues to grow rapidly to meet their target of 50% compound annual growth rate set in early 2021.

Tesla expects to maintain a compound annual growth rate of over 50% in 2023, with expected annual production reaching approximately 1.8 million vehicles.

Speaking of which, Musk should be most grateful to the Shanghai factory.

Tesla factories are located all over the world, but these factories have different production capabilities and statuses. Among them, the Shanghai factory remains Tesla’s production and export center.

Tesla Shanghai Gigafactory Sudden Bonuses

Last Friday, Reuters reported that three Shanghai Gigafactory employees revealed that the bonuses they received in the second quarter were 1.5 times their base salaries, higher than the previous 1.2 times. Moreover, it’s not just them getting an income increase, several colleagues around them also received similar bonus growth.

They suspect this bonus adjustment is related to the dissatisfaction that appeared in the factory 4 months ago. At that time, several workers complained about the bonus cuts on social media, and Musk immediately said he would investigate the matter.

Musk values the Shanghai Gigafactory for a reason, Tesla Shanghai has the fastest car production workshop in the world. After renovating the production line last July, the total annual production capacity of Tesla Shanghai factory reached 1.1 million units. Among them, the daily production capacity of Model 3 production line in Phase I factory can reach 1,200 units, and Model Y production line in Phase II factory is even higher, reaching 2,000 units.

It is learned that the Phase II factory has a total of 5 production lines, and can currently achieve a takt time of less than 40 seconds per car.

The 100,000th Model Y rolled off the production line at Tesla Shanghai factory. The time it took to produce this milestone, from the official launch of Shanghai made Model Y on January 1, 2021, was just 30 months.

On the other hand, the high production of the Shanghai factory affects more than just the Chinese market.

In May this year, Reuters reported that Tesla Shanghai factory has completed the first shipments to the North American market, sending China-made Model 3 and Model Y to Canada. Prior to this, electric vehicles produced at Tesla Shanghai factory had been exported to overseas markets such as Europe, Japan, and Australia.

Tesla China’s wholesale sales in the first half of this year were 464,000 vehicles. That is to say, in the first half of this year, among the 889,000 vehicles delivered globally by Tesla, more than 50% were produced at the Shanghai Gigafactory.

In the 2022 global pure EV sales rankings, Model Y took the crown with sales of 747,500. Musk believes Model Y can go further this year, moving beyond the pure electric field and aiming for the goal of becoming the world’s best-selling model in 2023 Tesla Model Y World’s Best-Selling Car, Topping Corolla and RAV4.

In Q2 earnings report, Tesla mentioned that with the strong momentum in the first quarter, Model Y has become the best-selling car in Europe so far.

In Musk’s view, the only reason stopping consumers from buying Tesla is that the price is not cheap enough, and production scale is directly linked to price.

In the just concluded Q2 earnings call, Musk mentioned that production will decline slightly in the third quarter as “we have to shut down the factories for upgrades in the summer.”

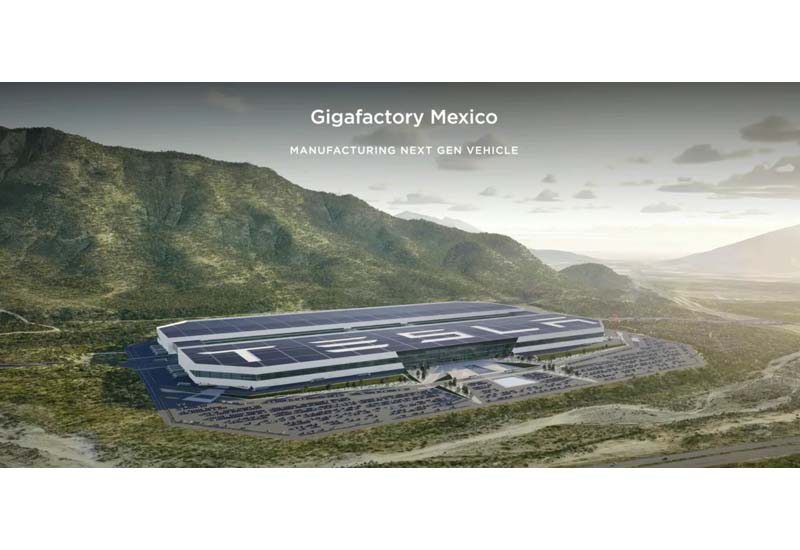

Tesla Mexico Gigafactory

Not only that, the Mexico Gigafactory is also on the way. In March this year, after the Tesla Investor Day ended, Tesla Senior Vice President Tom Zhu, who is in charge of building the Gigafactory, revealed to investors the completion time of the Mexico Gigafactory: Tesla’s internal goal is 9 months. And he believes it can be even faster, completed before the fourth quarter of this year.

Gigafactory Mexico is final permits? Tesla Model 2 Coming Sooner Than You Think

Although things have not gone as smoothly as Tom Zhu imagined, the Gigafactory located in Nuevo León, Mexico has now obtained all permits, with the planned completion time being Q1 2025 – Tesla’s final bottom line.

In order to ensure smooth production of this Gigafactory, which has a designed annual production capacity of 2 million vehicles on a land area of 15,000 acres, Tesla has made it clear to many Chinese auto parts suppliers:

If they cannot complete the localization of auto parts production in Mexico before 2025, it will not only be difficult to obtain orders from the new Mexican factory, but they may also lose orders originally exported to U.S. factories.

As a result, the on-time production of the Mexico factory has become almost inevitable.

But for Tesla, this is just a starting point. Musk hopes to build 10-12 Gigafactories to achieve Tesla’s goal of 20 million units annually by 2030.

Back to Tesla’s home base in Texas. In May this year, the Tesla lithium refinery in Corpus Christi, Texas officially broke ground. Musk said that improving lithium refining capacity is critical to advancing a sustainable energy economy.

In Musk’s view, Tesla has made considerable progress on raw materials and technology, thanks to Tesla’s superior working capital management capabilities. “I’m confident we can continue investing,” Musk said on the earnings call.

He gave an example: Tesla’s humanoid robot Optimus.

Tesla found that there are no suppliers in the world that can produce the actuators used in these robots, so they have to rely on themselves. And this obsession with technology will inevitably significantly increase Tesla’s value.

Tesla continues to push boundaries both technologically and structurally with products like the Cybertruck. Despite economic headwinds, the company remains confident in its ability to scale production globally thanks to factories like the one in Shanghai. Musk aims to keep investing in bleeding edge technology like Optimus robots that will further differentiate Tesla down the line. It’s this relentless drive that gives the company its edge.