Tesla has quietly been developing a revolutionary manufacturing technique that could reshape the industry. The company’s upcoming Cybercab Robotaxi model will be the first to showcase this innovative approach, dubbed the “unboxed process.”

According to Tesla’s head of vehicle engineering, Lars Moravy, the unboxed process represents a significant departure from traditional automotive assembly, (Tesla’s Revolutionary “Unboxed Process” Manufacturing for $25k Car). Rather than a linear, sequential production line, Tesla is embracing a modular architecture that enables parallel manufacturing of vehicle sections.

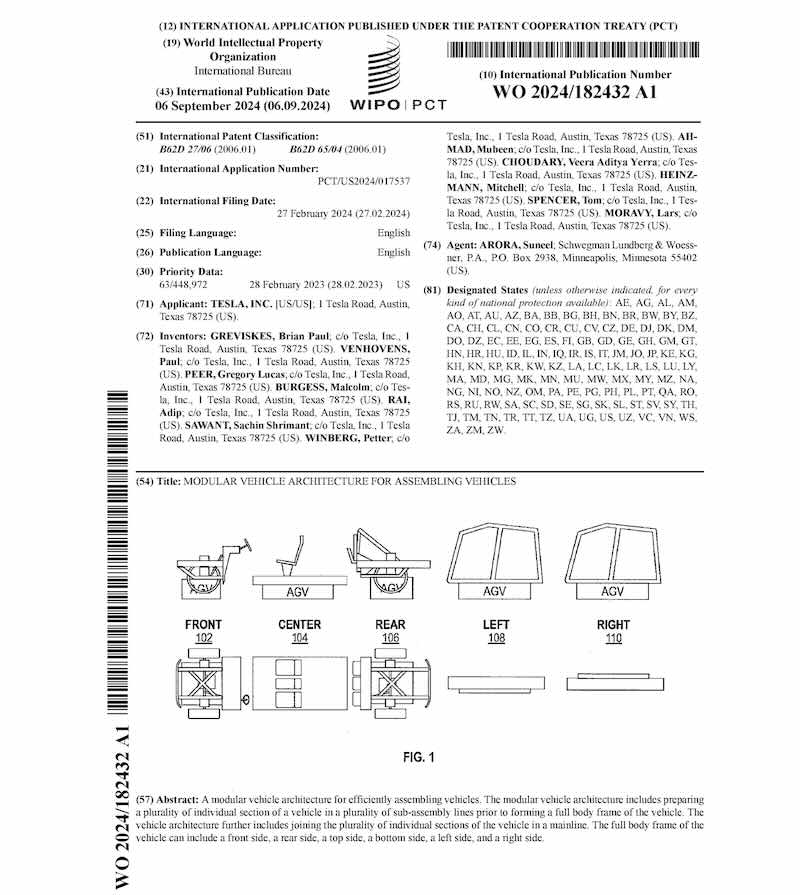

This modular approach, outlined in Tesla’s WO2024182432 patent, allows the company to streamline the assembly of its electric vehicles. By breaking down the vehicle into distinct, manageable components, Tesla can optimize the manufacturing workflow and reduce overall complexity.

The key to Tesla’s unboxed process lies in its automated framing station. This innovative technology facilitates the efficient joining of vehicle sections in multiple orientations. Rather than being confined to a single assembly line, the system can combine side panels horizontally while other components are aligned vertically.

The modular manufacturing journey begins with the processing of raw materials, followed by die-casting, blanking, stamping, and machining. These components then undergo a series of joining, decorating, sealing, and baking steps before the final assembly phase.

While the unboxed process may have broader applications, it appears particularly well-suited for vehicles with an exoskeleton structure, such as the upcoming Cybercab. This design approach aligns with Tesla’s vision, potentially allowing the Cybercab to share a similar silhouette to the divisive Cybertruck.

As the automotive industry continues to grapple with supply chain challenges and the need for agile, efficient production, Tesla’s unboxed process could emerge as a game-changer. By embracing a modular, parallel manufacturing strategy, the company aims to streamline its operations and deliver its electric vehicles to customers faster than ever before.

Whether the Cybercab will be the first to showcase this revolutionary approach remains to be seen, but one thing is certain: Tesla’s manufacturing prowess is about to be unboxed, and the industry is bracing for the impact.

Related Post

Elon Called Tesla Upcoming Purpose Built Robotaxi the “Cybercab”

Canaccord Genuity Analyst note: Tesla is increasingly a Bet on Autonomy

Tesla $25K EV Dream Hinges on Battery Power Couple with CATL