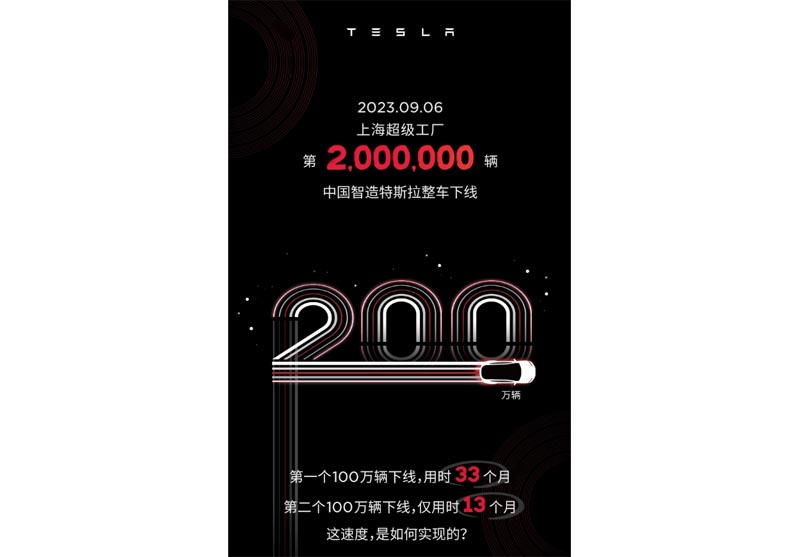

Tesla’s Gigafactory in Shanghai has produced its 2 millionth electric vehicle, the company recently announced. This massive milestone was reached just 13 months after building its 1 millionth car, showcasing the optimized manufacturing at Tesla’s key facility.

According to Tesla China, it takes under 40 seconds to fully assemble a Model 3 or Model Y at the Shanghai plant.

The factory employs a double-layer layout where robots nimbly grab car bodies mid-air, evoking a flying motion on the line. Production processes are further streamlined by having parallel workshops for front, middle and rear sections simultaneously rather than forcing strict sequencing.

Gigafactory Shanghai also houses a 6,000-ton die-casting machine that forms the entire rear underbody in one aluminum piece, consolidating 70 parts into one for added durability. Hundreds of robotic arms dominate the welding shop, needing just dozens of human workers compared to automakers of the past.

Throughout, a “digital neural network” tracks each vehicle’s components down to the number of screw turns and torque applied. Customers can even monitor their specific order’s status in real-time.

Sustainability is also touted at the facility, with 93% industrial waste recycling, 98% water reuse for industrial purposes, and wastewater treatment. Per Tesla, over 95% of vehicle components are locally sourced.

Gigafactory Shanghai optimized manufacturing techniques have supercharged Model 3 and Model Y production. Reaching 2 million total units in just over 2 years is a feat of impressive operational efficiency and technology. As Tesla continues expanding, watch for more conveyor-beltEV milestones powered by factories of the future.

Related Posts:

Tesla Expansion of GigaFactory Berlin to Pump Up Production capacity to 1 million vehicles

Construction Ramps Up at Tesla’s New Gigafactory Site in Mexico