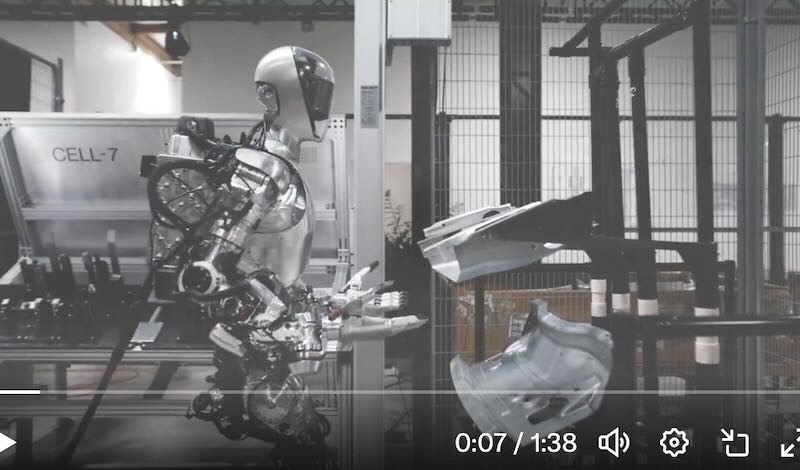

BMW has partnered with robotics startup Figure to introduce the Figure 001 humanoid robot to its Spartanburg plant, potentially revolutionizing the way we build cars.

Gone are the days when robots on assembly lines were confined to repetitive, single-purpose tasks. The Figure 001 humanoid robot, now strutting its stuff at BMW’s South Carolina facility, is ushering in a new era of flexibility and intelligence in automotive production.

Brett Adcock, the mastermind behind Figure Robot, couldn’t contain his excitement when discussing the partnership. “Figure + BMW Group’s Spartanburg Plant, Fully autonomous, AI-driven vision model, Neural Networks for all grasps,” he enthused, sounding more like a proud parent than a tech CEO.

But what’s the big deal? Aren’t robots old news in car factories?

The Figure 001 is a far cry from the robotic arms we’ve grown accustomed to seeing in manufacturing plants. This humanoid marvel is powered by AI and neural networks, allowing it to adapt to various tasks with unprecedented flexibility.

Key achievements of the Figure 001 include:

- Neural networks driving object manipulation by mapping camera pixels to robot actions

- AI systems placing sheet metal with sub-centimeter precision

- Navigation based purely on object training in simulation

In layman’s terms? This robot can see, think, and act with a level of autonomy that’s making waves in the industry.

The partnership between BMW and Figure isn’t just a flash in the pan. Announced in January 2024, this collaboration aims to bring general-purpose robots into automotive production on a grand scale.

“Single-purpose robotics have saturated the commercial market for decades, but the potential of general purpose robotics is completely untapped,” Brett Adcock explained. “Figure’s robots will enable companies to increase productivity, reduce costs, and create a safer and more consistent environment.”

BMW’s not just dipping its toes in the water, either. The company is diving in headfirst, with plans to explore advanced topics like artificial intelligence, robot control, and manufacturing virtualization alongside Figure.

While the Figure 001 is turning heads, it’s not without its growing pains. The robot’s movements are currently slower than a human worker’s, and it’s still tethered for power.

Dr. Robert Engelhorn, President and CEO of BMW Manufacturing, sees the bigger picture. “The use of general purpose robot solutions has the potential to make productivity more efficient, to support the growing demands of our consumers, and to enable our team to focus on the transformation ahead of us,” he stated, painting a vision of a future where humans and robots work in harmony.

As BMW and Figure continue to fine-tune their robotic workforce, the implications for the automotive industry – and manufacturing as a whole – are profound. Will other carmakers follow suit? How will this shift impact the labor market?

Figure 001 humanoid robot at BMW’s Spartanburg plant is more than just a novelty. It’s a glimpse into a future where AI and robotics reshape the way we build, work, and innovate. And for investors keeping an eye on the intersection of tech and manufacturing, this partnership could be the start of a very interesting ride.