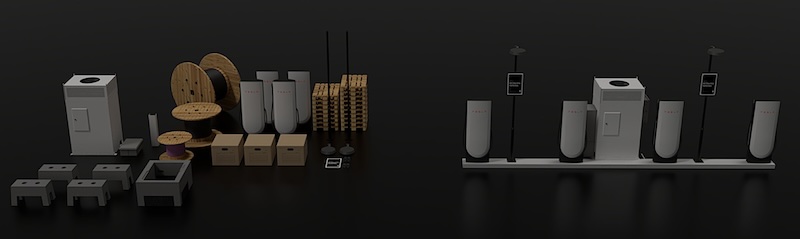

Tesla’s innovative approach to Supercharger installations is revolutionizing how we think about EV charging infrastructure. The company’s shift to pre-assembled charging stations, manufactured at facilities like Gigafactory New York, marks a significant evolution in deployment strategy.

Traditional Supercharger installations required extensive on-site construction work. Crews needed to perform time-consuming excavations, coordinate multiple contractors, and piece together components in the field. This process often led to longer deployment times and higher costs.

The new prefabricated approach streamlines the entire process. These pre-assembled units arrive ready for installation, dramatically reducing on-site work and cutting down deployment timelines. Max de Zegher, Tesla’s North American director of charging, emphasizes that this factory-based assembly ensures higher quality control while lowering costs.

These efficiency gains translate directly to consumer benefits. The streamlined installation process reduces labor costs, minimizes potential delays, and maintains consistent quality standards. Tesla confirms these savings are being passed directly to drivers through competitive charging rates.

Factory assembly allows for rigorous testing before deployment. Each unit undergoes standardized quality checks in controlled conditions, reducing the likelihood of issues that might arise from field assembly. This systematic approach ensures greater reliability across the charging network.

The prefab strategy also reduces the environmental impact of installations. Less on-site construction means:

- Reduced heavy equipment usage

- Minimal ground disruption

- Lower noise pollution

- Decreased construction waste

Local communities see faster implementation with less disruption. What once took weeks of construction now requires only days, minimizing impact on nearby businesses and residents.

This shift represents more than just operational efficiency. It demonstrates Tesla’s commitment to rapid infrastructure expansion while maintaining quality and cost-effectiveness. As the EV market grows, such innovations will prove crucial for meeting increasing charging demands.

Related Post

Tesla 168-Stall Lost Hills Supercharger: World Largest Solar-Powered EV Station Coming 2025

Tesla Now Lets Owners Order Food for Pickup at Supercharger Stations in UK

Tesla Superchargers Now Open to GM EVs Throughout the United States and Canada