In the world of tech, few things capture the imagination quite like humanoid robots. As companies like Figure, a $2.6 billion unicorn in the robotics space, set their sights on mass production, a pressing question arises: Can humanoid robots be manufactured at scale like smartphones, or are they more akin to the complex assembly lines of the automotive industry?

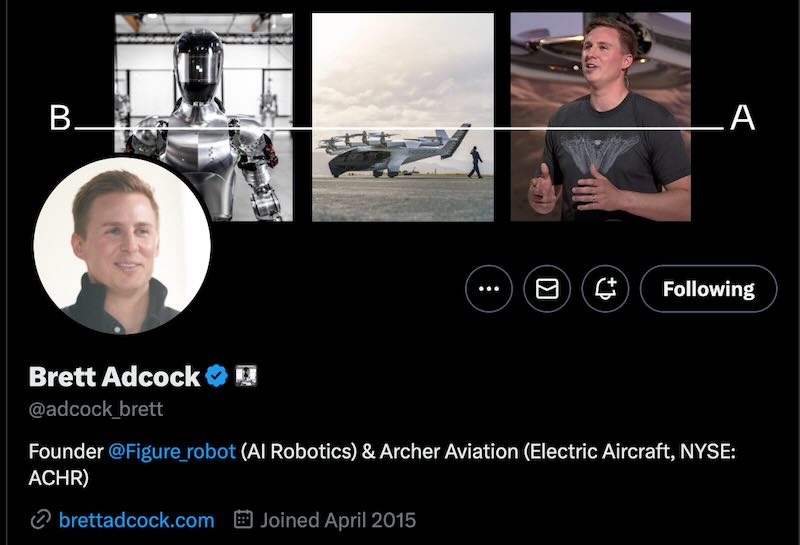

Brett Adcock, Figure’s CEO, has been grappling with this very conundrum. In a X article, he laid out his thoughts on the subject, and let’s just say, it’s not as straightforward as you might think.

“Since starting Figure, I’ve always been interested in getting to scale manufacturing for humanoid robots,” Adcock wrote. “And I’ve been curious recently: Are humanoid robots more similar to manufacturing a cell phone (consumer electronics) or cars?”

After spending a considerable amount of time pondering the intricacies of robot manufacturing, Adcock seems to have landed on the side of consumer electronics – with a few caveats, of course.

“It seems clear that humanoid robots will resemble consumer electronics much more than cars,” he explained, citing a few key factors:

- Humanoid robots weigh about 25 times less than a car, making them easier to handle.

- They have roughly the same number of parts as a smartphone and around 10 times fewer parts than a typical car.

- You can hold any single robot part in your hands, much like a phone component – try doing that with a car chassis.

Don’t go thinking robot manufacturing is a walk in the park just yet. Adcock acknowledged the challenges ahead, noting that “the next few years will be both exciting and challenging” as Figure ramps up its production lines and expands its manufacturing team.

One topic that’s sure to come up in any discussion of robot manufacturing is 3D printing. After all, what could be more futuristic than printing out your very own personal android?

Adcock, however, seems to be taking a more pragmatic approach. “We do a decent amount of non-structural 3D printing today, but within our high production line, almost none of the robot will be 3D printed,” he said. “You just can’t beat the cost of traditional manufacturing methods (stamping, casting, molding) – not even close.”

That said, he did acknowledge the value of 3D printing for early prototyping and tooling, calling it “useful” in that context.

Of course, no discussion of humanoid robots would be complete without mentioning Tesla’s much-hyped Optimus project. Designing humanoid robots is incredibly complex, requiring the development of motors, gearboxes, sensors, and electrical systems from scratch, the article notes. This is often beyond the capabilities of startups. However, Tesla excels in electrical and mechanical engineering and has the resources to tackle these challenges.

Tesla’s strength in manufacturing, engineering, and AI gives it a significant advantage, Tesla’s AI, already used in their cars, can be directly applied to robots like Optimus. Adcock’s insights may have been a well-timed response to Elon’s recent shareholder meeting, in the high-stakes world of robotics and autonomous vehicles, even the slightest shift in narrative can raise investor concerns.

As the article concludes, entrepreneurship is challenging. In the realm of autonomous vehicles and robotics, opportunities seem limited to a few advanced tech and automotive companies. If Adcock’s comments are any indication, Figure is determined to be one of them.

The race to mass-produce humanoid robots is on, and it’s shaping up to be a wild ride. Stay tuned for more updates from the frontlines of this fascinating and rapidly evolving industry.